Businesses want smaller batch sizes, increased color ranges, the ability to print variable data, as well as fast turnaround.

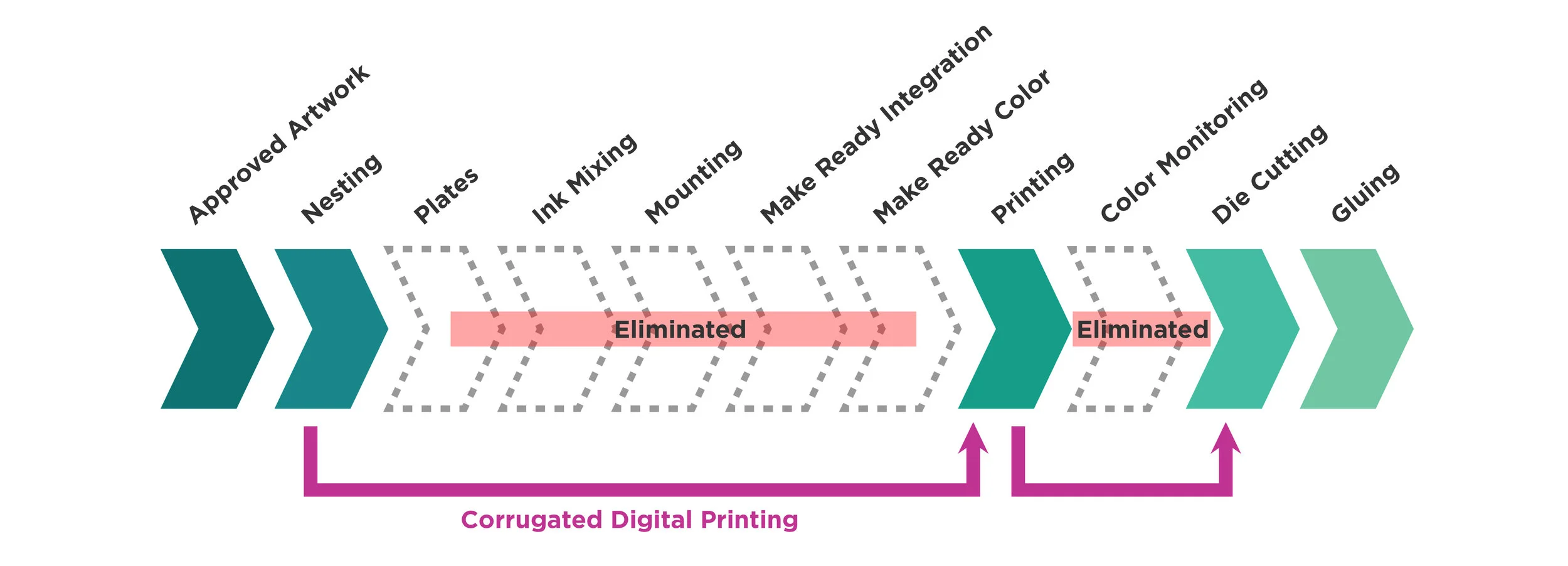

With the Barberan 1260, ColorHub meets these demands. Our single pass, digital print process eliminates several steps, allowing your artwork to flow directly from a computer to the press.

With a wickedly efficient process, ColorHub eliminates the cost and time associated with print plates and press setup, enabling speeds and low volumes that the industry has never seen and allowing for creative change without changeovers.

BENEFITS

Low Volume Access

The digital print process renders print plates obsolete, removing the associated costs and design restrictions. Low volume jobs that would otherwise need print plates can be easily executed, saving you money and enabling opportunities for future design changes. But don't be fooled, digital printing isn't just for small runs.

Production Speed

The Barberan Jetmaster can print up to 180 linear feet per minute, which translates to approximately 66,000 square feet per hour. As the first single pass print press in the corrugated industry, the Barberan Jetmaster is over 10 times faster than fastest multi pass digital press available, over 100 times faster than most digital presses currently in use.

Operation Efficiencies

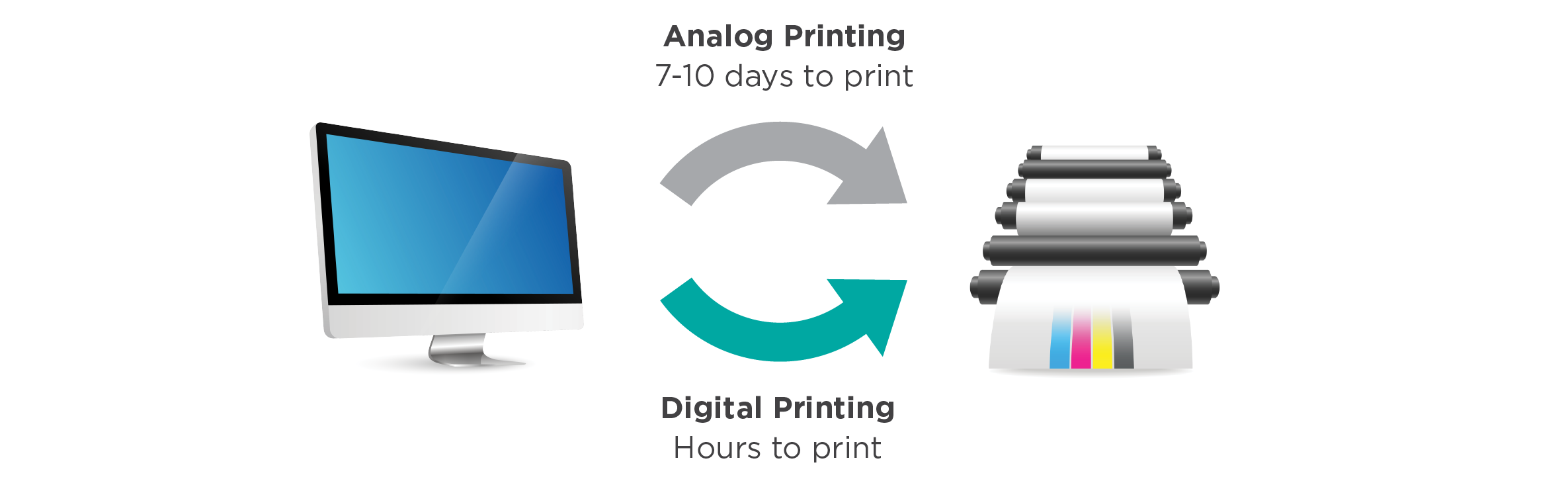

The speed of the digital process enables fast turnarounds and just in time production. In addition to eliminating print plates, the digital print process streamlines press setup so that switching between print jobs is almost instantaneous. Additionally, from the time a job is created, the traditional, analog print workflow requires 7-10 days to print, whereas the digital workflow requires mere hours to print. This streamlined process creates operation efficiencies, saving both time and money.

Mid-Production Creative Changes

The digital print process allows for creative change without changeovers. In other words, our workflow lets us print jobs of the same design or continuously change between designs without any machine stops or set up. The ability to change designs on the fly provides you with dramatic creative possibilities.

Color Range + Consistency

With a 6 color Barberan, ColorHub boasts a wide color range with CMYK as well as Orange and Violet UV inks. The use of these 6 colors cover approximately 90% of the Pantone coated color gamut, whereas standard CMYK coverage is only 75%.

Additionally, the Barberan’s printing process eliminates the traditional color mixing and monitoring steps, ensuring strict brand management. In traditional print processes, inks are pre-mixed and then adjusted during production to achieve consistent results. With the Barberan, once artwork colors are approved, the colors are set and will be consistent across runs. Colors are not pre-mixed, but are rather mixed on the board. The print heads drop various combinations of the 6 inks to achieve specific colors.